DIP Peripheral Equipment: Essential Tools for Efficient Through-Hole Soldering

DIP peripheral equipment streamlines through-hole soldering with auto lead formers, flux applicators, and synchronized conveyors. Precision lead prep ensures components fit perfectly, while selective flux application enhances solder joint integrity. Integrated AOI systems detect defects mid-process, slashing rework by 40%. Compliant with IPC-A-610, these tools reduce manual handling and boost throughput by 35%. Energy-efficient designs cut power costs by 20%, ideal for automotive, industrial, and power supply manufacturing. By automating prep, application, and inspection, they transform labor-intensive soldering into a seamless, high-yield workflow—where precision meets productivity in demanding PCB assembly environments.

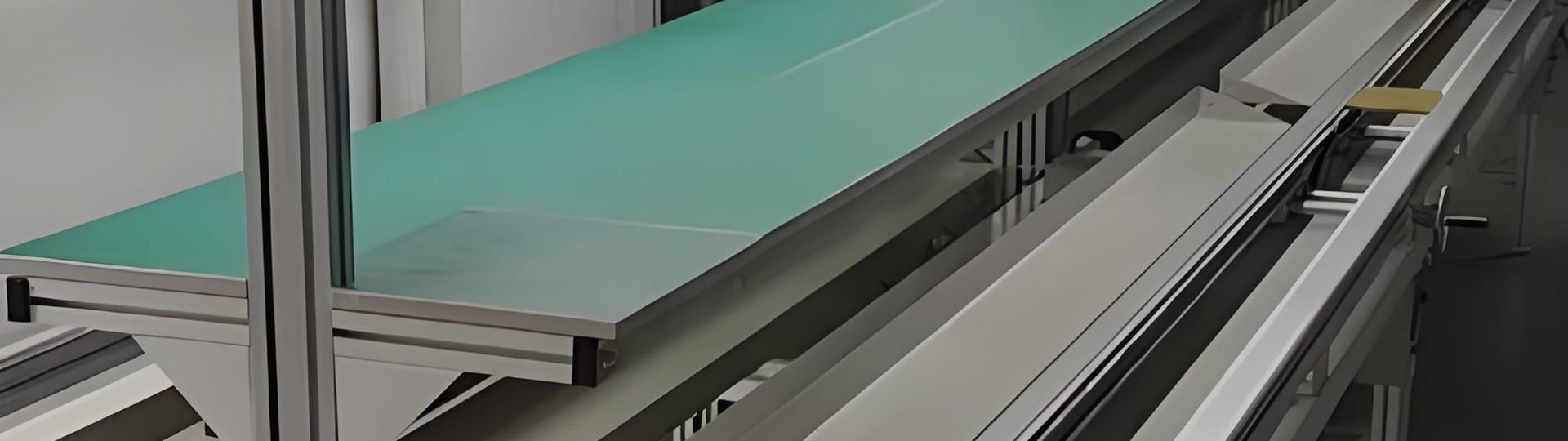

How DIP Peripheral Equipment Enhances Workflow in PCB Manufacturing

DIP peripheral equipment optimizes workflows by automating component prep, insertion, and inspection. Auto-feeders sort and align axial/radial parts, while vision-guided conveyors ensure precise PCB positioning. In-line lead trimmers and flux applicators eliminate manual steps, boosting throughput by 50%. Real-time IoT monitoring predicts jams or misalignments, reducing downtime by 30%. Modular designs integrate seamlessly with existing lines, supporting high-mix production of medical devices, telecom routers, and energy systems. IPC-610-compliant defect detection slashes rework by 45%, ensuring reliability in harsh environments. By bridging automation gaps, these tools transform fragmented processes into streamlined, error-free workflows—where speed, precision, and scalability redefine PCB manufacturing efficiency.