CY PCBA Conformal Coating Line Equipment Solutions

Customers can select the suitable conformal coating application solution based on their actual production needs.

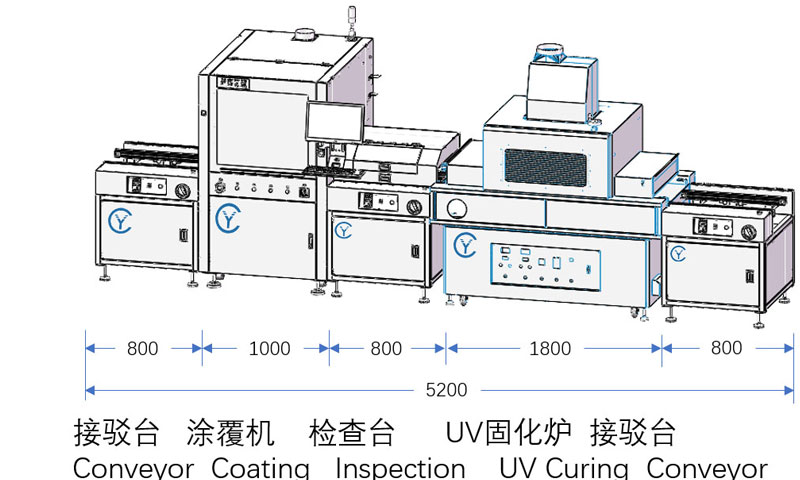

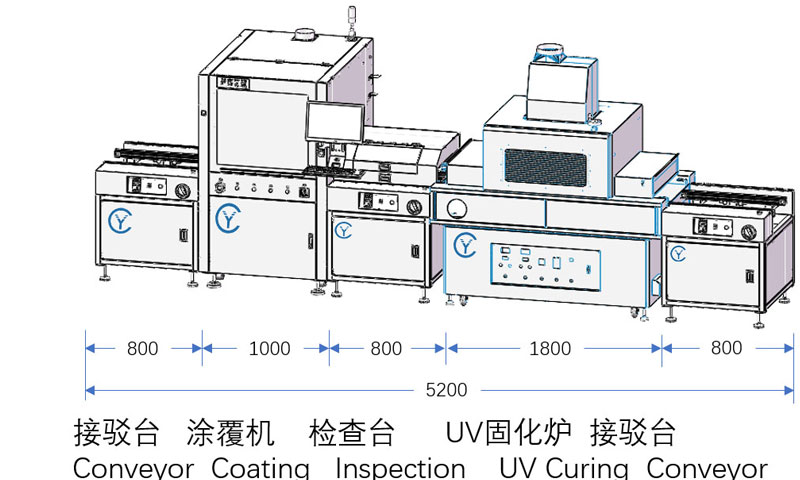

1. Standard UV Oven Conformal Coating Line- Suitable for coating materials cured by UV lamps

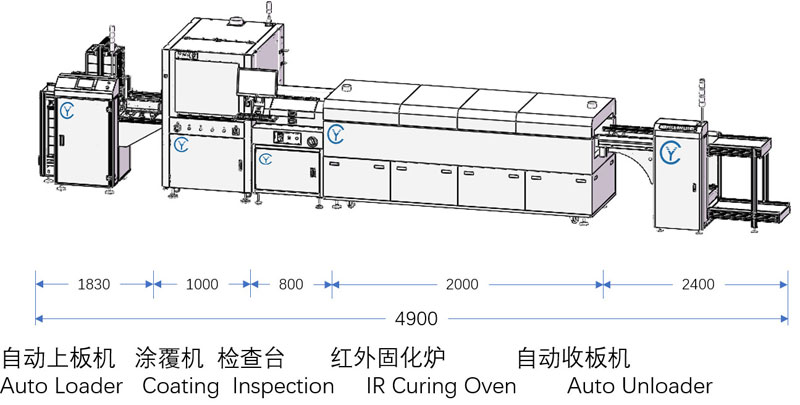

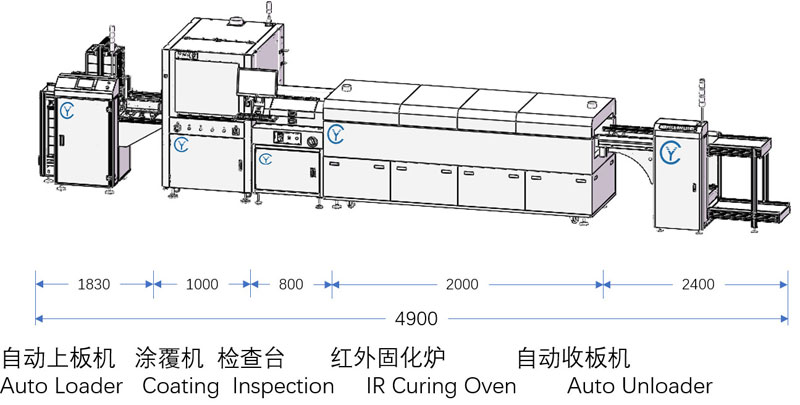

2. Loader/Unloader Conformal Coating Line

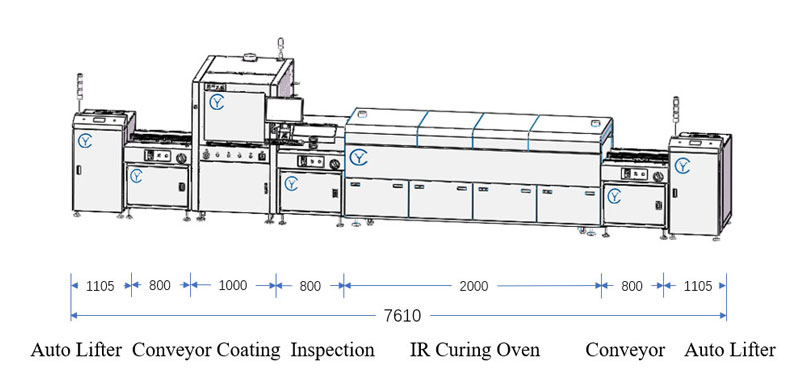

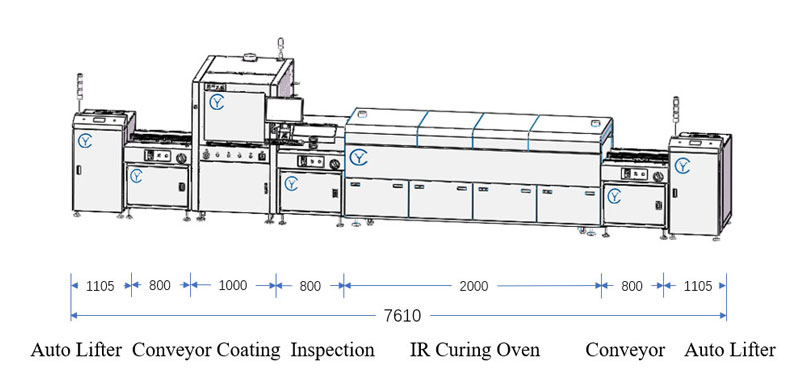

3. Lifting Reflow Conformal Coating Line- This solution can reduce labor costs, as a single operator is capable of managing the entire production line.

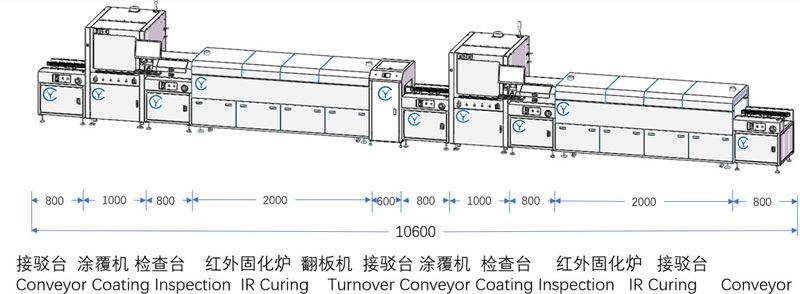

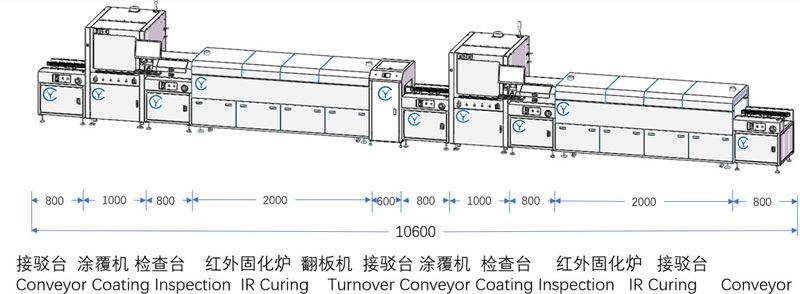

4. Dual-Coating Machine System- This solution accommodates dual-side selective Coating/dispensing for circuit boards.