| Model | CY-350T/350N- |

| The heating part parameters |

|

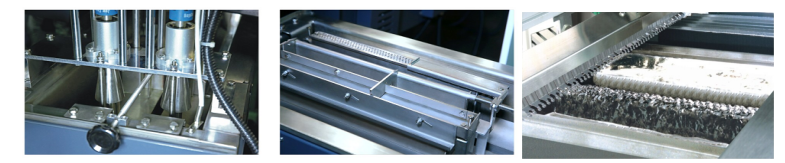

| Spray head movement method | Stepper Motor |

| Flux storage tank | 6 LITRES |

| Spray pressure | 3-5BAR |

| Preheating system parameters |

| Preheating Mode | Hot Air Preheating |

| Preheating Zone Number | 4-Stage Preheating |

| Preheating Lenghth | 1800mm |

| Warm-up Time | Approx.15min |

| Transportation part parameters |

| PCB maximum width | 350mm |

| Guide the wide range | 50-350mm |

| Conveyor Speed | 0-2000mm/min |

| Conveyor Height | 750±20mm |

| Transport direction | L→R(R→L) |

| soldering angle | 4-7° |

| Transportation part parameters |

| Solder temperature | 9KW(Room temperature-300℃) |

| Solder capacity | 400Kg |

| Control part of the parameter |

| Control method | Branded Computer (Windows Operating System) + Siemens PLC |

| Transport motor | 3∮ AC380V 90W, |

| Wave motor | 3∮ AC220V 360W*2pcs, |

| Finger cleaning pump | 1P AC220V 10W |

| Fingers | Custom Titanium Alloy Double-Groove Claw |

| Cooling system | Forced Air Cooling |

| The power supply | 5-Wire, 3-Phase 380V, 50/60Hz |

| Starting power | 38Kw |

| Normal operating power | Approx10Kw |

| Temperature control mode | Full Computer PID Closed-Loop Control, SSR Drive |

| Abnormal alarm | Temperature Abnormality (Excessively High or Low After Stabilization) |

| Three-color warning light | Three-Color Signal Light: Yellow - Heating; Green - Temperature Stabilized; Red - Abnormal |

| Nitrogen parameters |

| Oxygen content in nitrogen gas source | ≤10PPM |

| Nitrogen source pressure | 0.5-0.8Mpa |

| Number of nitrogen flow meters | 1 |

| The body parameter |

| Weight | Approx.1800Kg |

| Installation dimension(mm) | L4300×W1530×H1700 |

| Exhaust air requirements | 10 Cubic Meters per Minute, 2 Channels, Ø200mm |