Easy and accurate positioning using servo system.

High-speed guide rail and Delta inverter motor are used to drive the scraper seat to ensure printing accuracy.

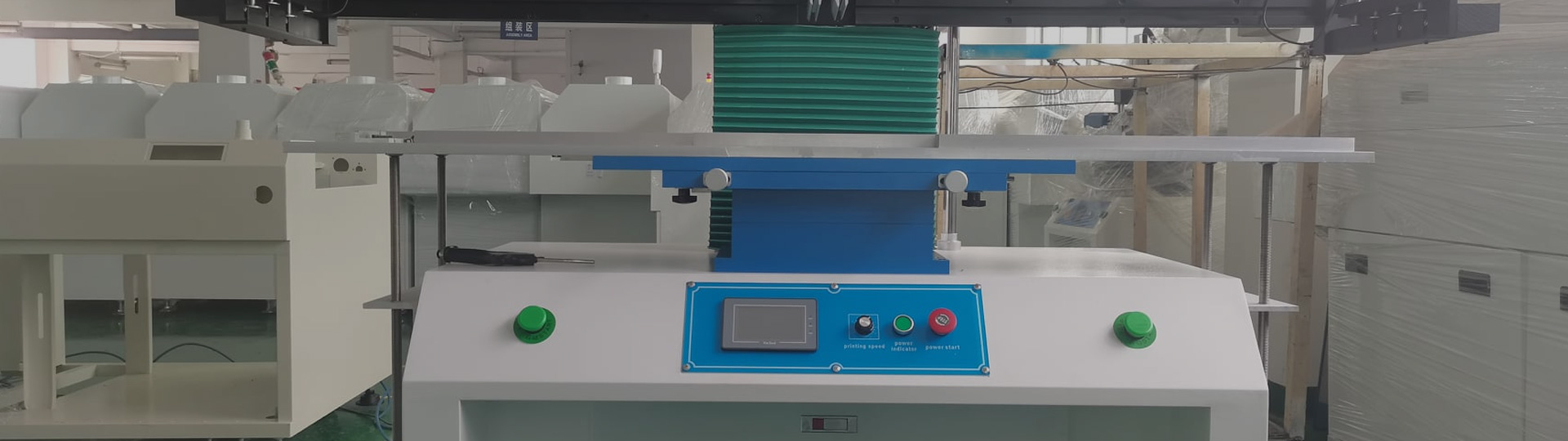

The printing squeegee can be rotated upwards and fixed 45 degrees, which is convenient for cleaning and replacing the printing screen and squeegee.

The scraper seat can be adjusted back and forth to choose the proper printing position.

The combined printing platen has a fixed groove and a PIN, which is convenient for installation and adjustment, and is suitable for single and double-sided printing.

The school version adopts stencil movement and combined with printed X, Y, and Z. Easy and quick calibration.

2N PLC and imported touch screen man-machine interface control, simple, convenient and more suitable for man-machine dialogue.

One-way and two-way printing can be set.

It has automatic counting function, which is convenient for the statistics of production output.

The scraper angle can be adjusted. Steel scraper and rubber scraper are suitable.

The man-machine interface has a screen saver function to protect the life of the man-machine interface.

Unique programming design, easy adjustment of printing scraper seat.

Printing machine speed, man-machine interface display, can be digitally adjusted and controlled arbitrarily.