Features of GKG H1200

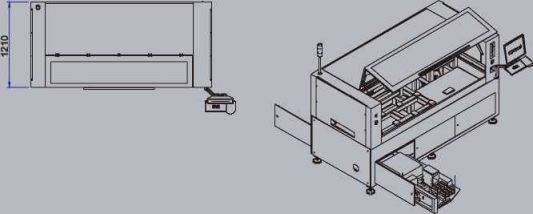

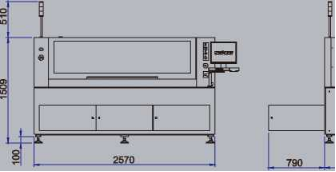

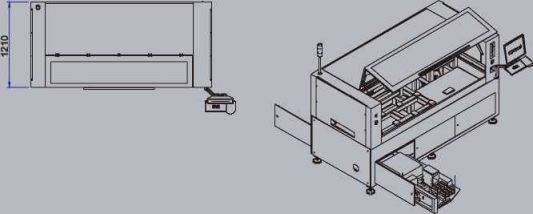

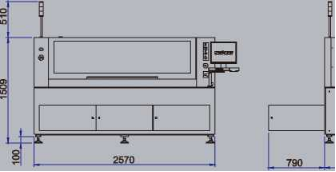

H1200 meets 1200 * 350mm supersize printing process requirements

Using uniform ring light and high brightness coaxial light, with promise brightness adjustment function, then all types of Mark points can be well recognized (Including the rugged Mark points), applicable for tin plating, coppering, gold plating, tin spraying, FPC and other types PCB with of different colors. With GKG patent mathematical model, able to ensure high accuracy.

Safe and tidy distribution of electric circuit and gas circuit Electric circuit and gas path are positioned vertically at the two sides and the back of machine, which is easy to check and repair.

The machine adopts windows XP/win7 operating interface with GKG user friendly software. Chinese/English selectable, Menu/Operating Journal/Breakdown Record/Breakdown Diagnosis/Error Analysis/Light Alarm etc.

The 2D system immediately detects solder paste deposition defects such as deviation Jack paste, miss paste,paste joint etc, and

Unique long platform and track fixed design, to ensure stable support PCB.Short squeegee horizontal printing, pressure stability,save solder paste.