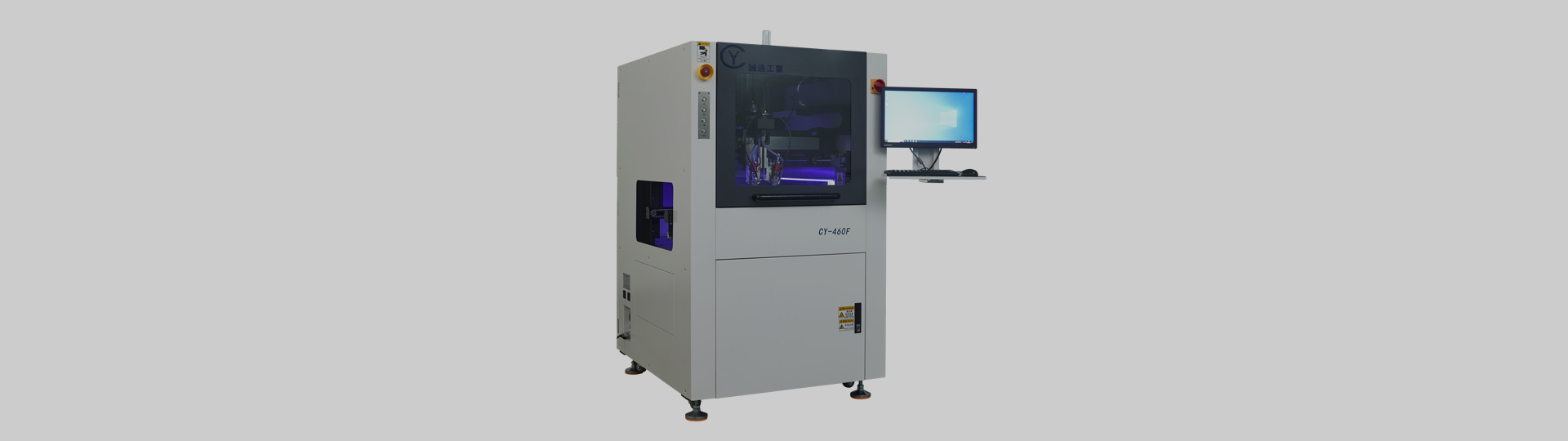

Features of CY-460F Four-Axis Selective Conformal Coating Machine

1. The CY-460F is controlled by an industrial computer and runs on the Windows operating system.

2. The CY-460F can be equipped with two or more sets valves at the same time, increasing production capacity and achieving panel spraying.

3. CY-460F equipped with a coating valve automatic soaking and automatic liquid dispensing device, it can eliminate valve nozzle blockage and facilitate quick and easy maintenance.

4. Online track design that can be connected other equipment online

5. Support offline programming and manual demonstration programming methods

6. Configure exhaust gas discharge outlet

7. Equipped with SMEMA interface for communication with other devices

8. Optional Coating materials quantity and liquid level alarm system

9. Optional CCD visual positioning system.

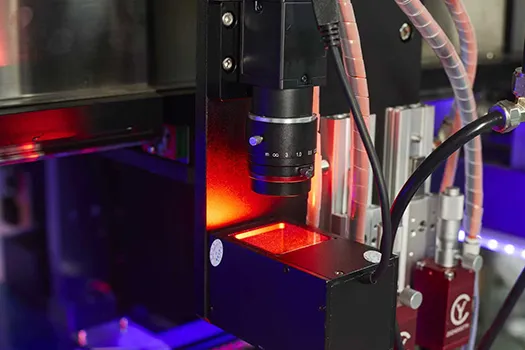

Coating valves of CY-460F Four-Axis Selective Conformal Coating Machine

JC-200M, cone type atomizing valve

JC-200N, Precision spray valve

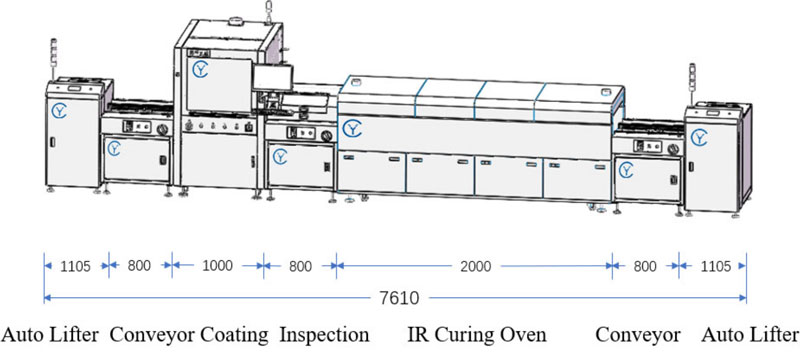

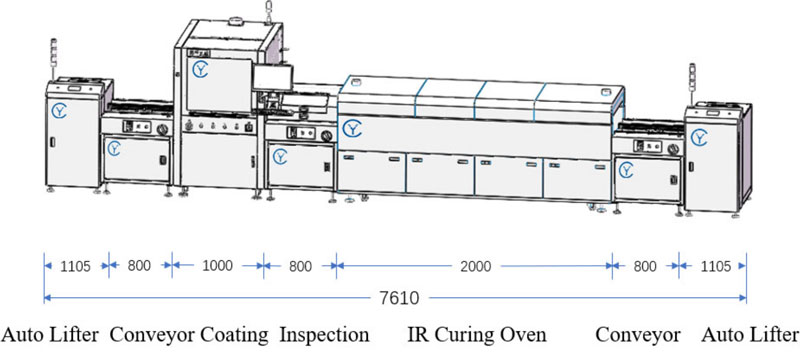

Conformal Coating Line solutions examples of CY-460F Four-Axis Selective Conformal Coating Machine

Company

Certifications

Exhibitions

Packing