| Series | N Series |

| Model | CY-F820-N | CY-F1020-N | CY-F1220-N |

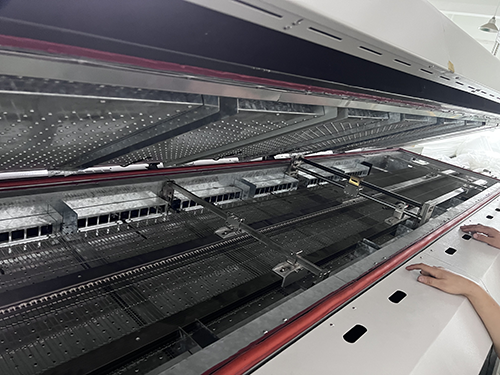

| The heating part parameters |

| Number of heating zones | Up 8/Down 8 | Up10/Down 10 | Up12/Down12 |

| Number of cooling zones | Top2/Down2 (Standard) 上Top3/下Down3(Optional) |

| Heating zone length | 2790 mm | 3900 mm | 4640 |

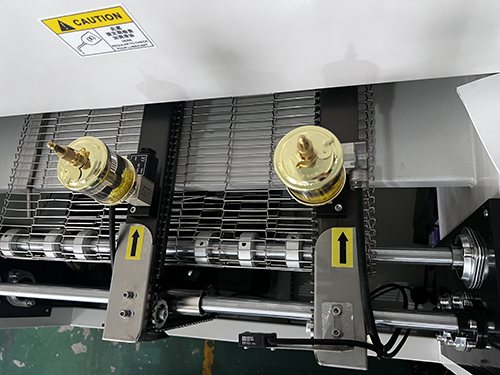

| Transportation part parameters |

| PCB maximum width | Rail type 50-450mm |

| Transport direction | Standard L→R Optional(R→L) |

| Guide rail fixed way | Front(Optional:Backend) |

| Conveyor belt speed | Mesh belt 875±20mm,Chain 900±20mm |

| Transmission way | Stainless steel chain drive + mesh drive |

| Conveyor belt speed | 300-2000mm/Min |

| Control part of the parameter |

| The power supply | 380V 50/60Hz / 5-wire 3-phase 380V 50/60Hz |

| Starting power | 38Kw | 58Kw | 76Kw |

| Normal work consumed power | Approx.7.5Kw | Approx.8.5Kw | Approx.10.5Kw |

| Heating up time | About 15-20 mins |

| The temperature control range | Room Temper ature-300℃ |

| Temperature control mode | Fully computerized PID closed-loop control, SSR driver |

| The whole machine control mode | Computer +PLC |

| The temperature control precision | ±1℃ |

| The deviation of PCB temperature distribution | ±1-2℃ |

| Cooling way | Nitrogen generator: water-cooled |

| Abnormal alarm | Abnormal temperature (ultra-high or ultra-low after constant temperature) |

| Three color light | Tri color signal light: yellow - heating up; Green - constant temperature; Red - Abnormal |

| The body parameter |

| Weight | Approx.1700Kg | Approx.1900Kg | Approx.2200Kg |

| Installation dimensions(mm) | L5050×W1400×H1450 | L5750×W1400×H1450 | L6500×W1400×H1450 |

| Exhaust air requirements | meters per minute, 2 channels with a diameter of 200MM |

| Nitrogen part (option) |

| Nitrogen protection device | Nitrogen flow rate of 20-30 cubic meters per hour, oxygen concentration of 500-800PPM |

| The external water cooling system | cooling speed ≥ 6 ℃/sec |