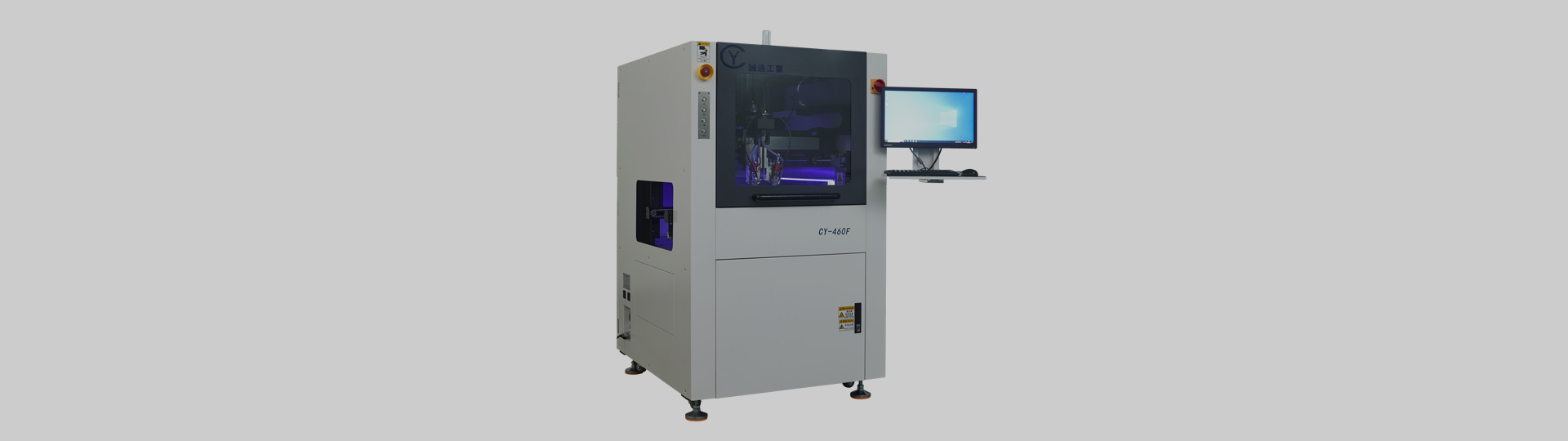

Four-Axis Selective Conformal Coating Machine: Achieving Ultimate Coating Precision

This machine elevates precision with a fourth rotational axis (A-axis), enabling multi-angle coating on 3D PCB assemblies. It navigates complex geometries—double-sided boards, tall components, or irregular shapes—by dynamically adjusting spray angles for uniform coverage without masking. Vision-guided alignment and collision-avoidance algorithms ensure micron-level accuracy, even in shadowed areas.

Compatible with high-performance coatings (e.g., UV-curable resins), it reduces cycle times while adhering to IPC and MIL specs. Real-time monitoring prevents material waste, ideal for automotive ECUs, medical implants, and aerospace systems where flawless, omnidirectional protection ensures longevity in extreme operational environments.

How a Four-Axis Selective Conformal Coating Machine Reduces Material Waste?

The four-axis system minimizes waste through adaptive flow control and optimized spray paths, targeting only critical areas with minimal overspray. Its rotational axis enables precise angled application, eliminating excess material buildup on complex 3D components. Intelligent software calculates exact coating volumes, while real-time sensors adjust dispensing to avoid drips or gaps.

By eliminating manual masking and reducing rework from errors, it cuts material usage by up to 30%. Compatible with low-waste technologies like jetting valves, the automated conformal coating machine supports eco-friendly coatings, aligning with lean manufacturing goals. Ideal for high-value industries, it ensures resource-efficient protection for PCBs in EVs, robotics, and industrial automation.