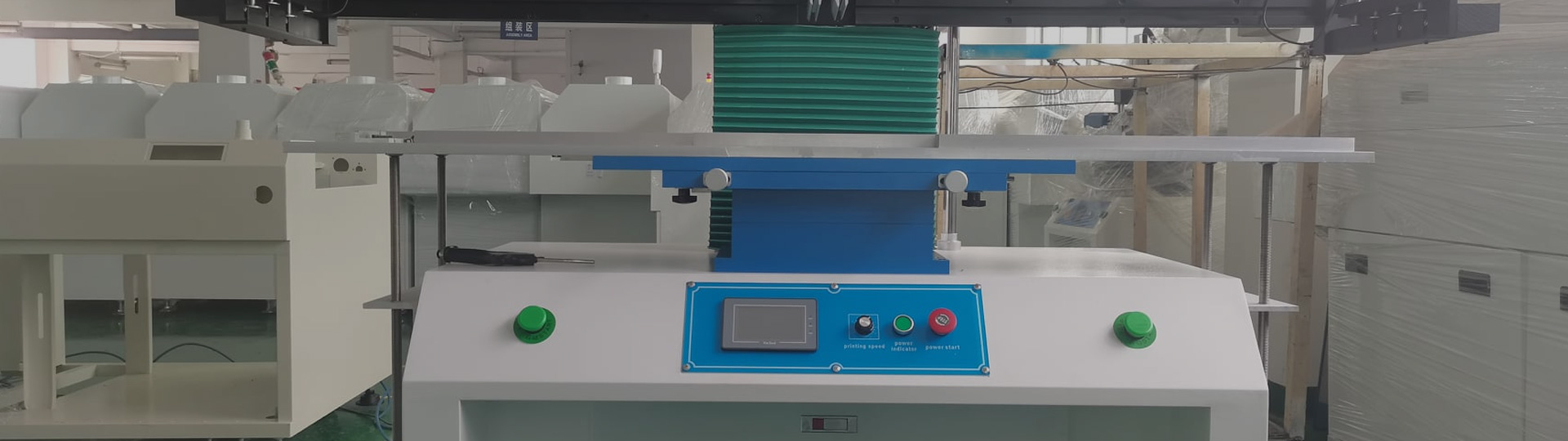

Semi-Automatic Solder Paste Printer: A Cost-Effective Solution for PCB Stencil Printing

Designed for small-batch or prototype PCB assembly, this printer blends affordability with precision. Manual board handling reduces upfront costs, while vision alignment ensures ±50µm accuracy for 0603 components and 0.5mm-pitch ICs. Adjustable squeegee pressure and stencil clamping optimize paste deposition, minimizing bridging or skips. Compact and user-friendly, it supports lead-free, no-clean pastes and complies with IPC-7525 basics. Ideal for R&D labs, repair stations, or low-volume IoT/industrial control production, it offers a budget-friendly entry into reliable stencil printing—where flexibility, ease of use, and consistent quality matter most for lean manufacturing workflows.

How a Semi-Automatic Solder Paste Printer Enhances Soldering Accuracy

This printer boosts precision with vision-assisted alignment (±50µm) and adjustable squeegee pressure, ensuring consistent paste deposits for 0603 components or 0.5mm-pitch BGAs. Manual loading paired with automated stencil clamping minimizes human error, while laser-etched stencils optimize aperture fill rates. Real-time pressure feedback prevents over/under-printing, reducing rework by 70%. Compatible with lead-free and no-clean pastes, it adheres to IPC-7525 standards for solder volume and alignment. Ideal for prototyping or low-volume production, it bridges affordability and accuracy—perfect for industrial controls, IoT devices, and educational labs where precise soldering starts define end-product reliability.