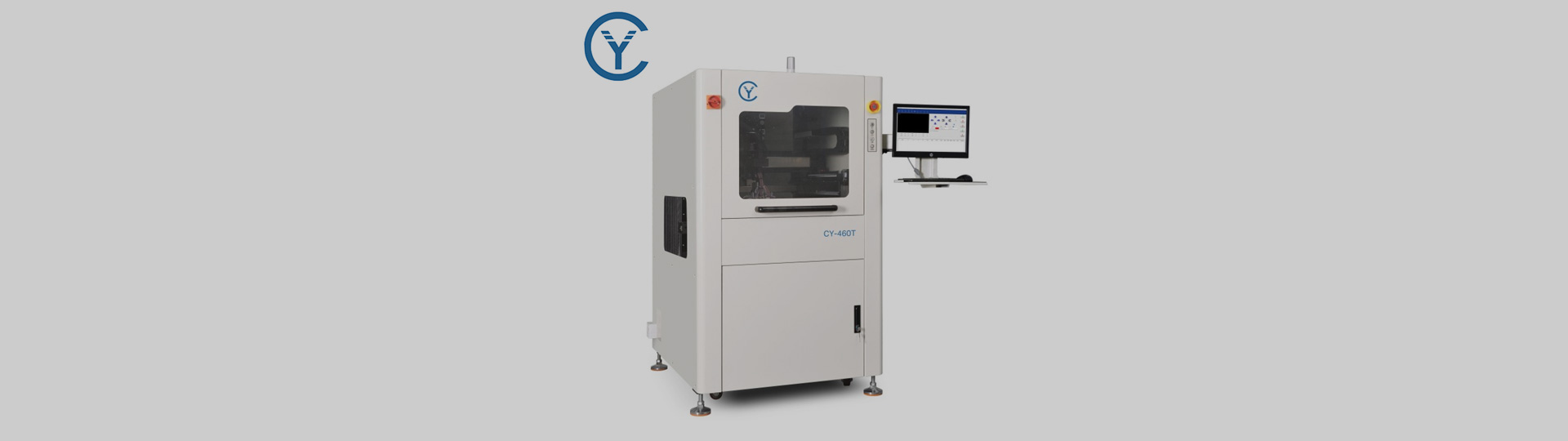

Three-Axis Selective Conformal Coating Machine: Precise Coating for Complex PCB Designs

This machine delivers micrometer-level accuracy for intricate PCB layouts, dynamically adjusting coating paths in real-time via programmable three-axis motion. It excels in masking fine-pitch components, connectors, and micro-vias while ensuring uniform material distribution across uneven surfaces. Equipped with adaptive flow control, it handles varying board thicknesses and high-density assemblies without clogging. Real-time diagnostics monitor spray consistency, preventing under/over-coating defects. Compatible with nano-coatings for ultra-thin layers, it meets MIL-I-46058C specifications for military and telecom hardware. By combining speed with exacting repeatability, the system reduces rework and ensures compliance in mission-critical applications where design complexity demands flawless environmental protection.

Why Choose a Three-Axis Selective Conformal Coating Machine for Electronic Protection

This machine offers unmatched versatility, adapting to diverse PCB geometries and production volumes with rapid programming and tool-free changeovers. Its three-axis precision eliminates masking needs, reducing labor and material costs while coating tight spaces like under components or between pins. Intelligent path optimization minimizes cycle times and ensures 100% coverage on high-reliability boards. Compatible with eco-friendly, low-VOC coatings, it aligns with sustainability goals. Scalable for R&D prototyping or full-scale production, the system future-proofs manufacturing lines, delivering defect-free protection for automotive sensors, IoT devices, and wearable tech where miniaturization and environmental resilience are paramount.