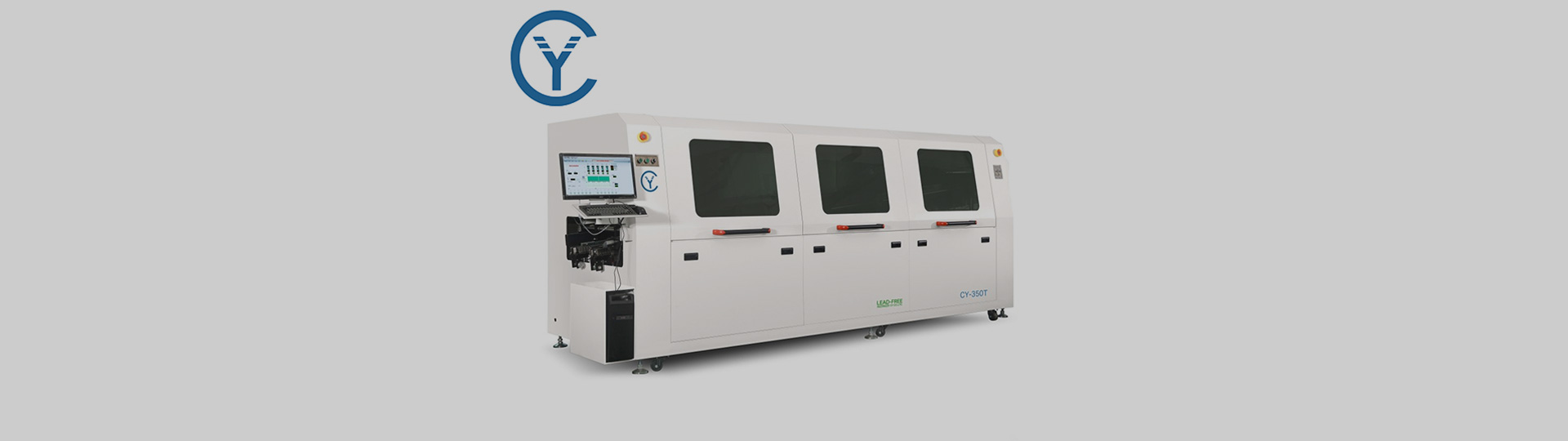

PCB Wave Soldering Machine: Reliable Soldering for Through-Hole Components

This machine ensures robust solder joints for through-hole components via optimized dual-wave technology, achieving<0.5% defect rates. Adjustable preheat zones and nitrogen inertion eliminate thermal stress and oxidation, perfect for high-density or mixed SMT/THT boards. Intelligent flux spray systems reduce consumption by 30%, while conveyor speeds (0.5–6m/min) adapt to PCB sizes up to 600mm. Compliant with IPC-J-STD-001, it guarantees reliability in automotive, power supplies, and industrial controls. Energy-efficient designs cut power use by 25%, and self-cleaning solder pots minimize downtime. Ideal for harsh environments, it delivers unmatched durability—where precision, speed, and flawless soldering define mission-critical electronics manufacturing.

PCB Wave Soldering Machine Working Principle

A wave soldering machine boosts efficiency by automating high-speed soldering (up to 6m/min) for through-hole components, reducing defects to<0.5% via dual-wave technology. Nitrogen inertion ensures oxidation-free joints, while adaptive preheat zones and flux control optimize thermal profiles for mixed SMT/THT boards. Self-cleaning solder pots slash maintenance downtime, and energy-saving modes cut costs by 25%. IPC-J-STD-001 compliant, it accelerates throughput for automotive, industrial, and power electronics—where precision, scalability, and 60% rework reduction transform high-volume production into a streamlined, cost-effective process.