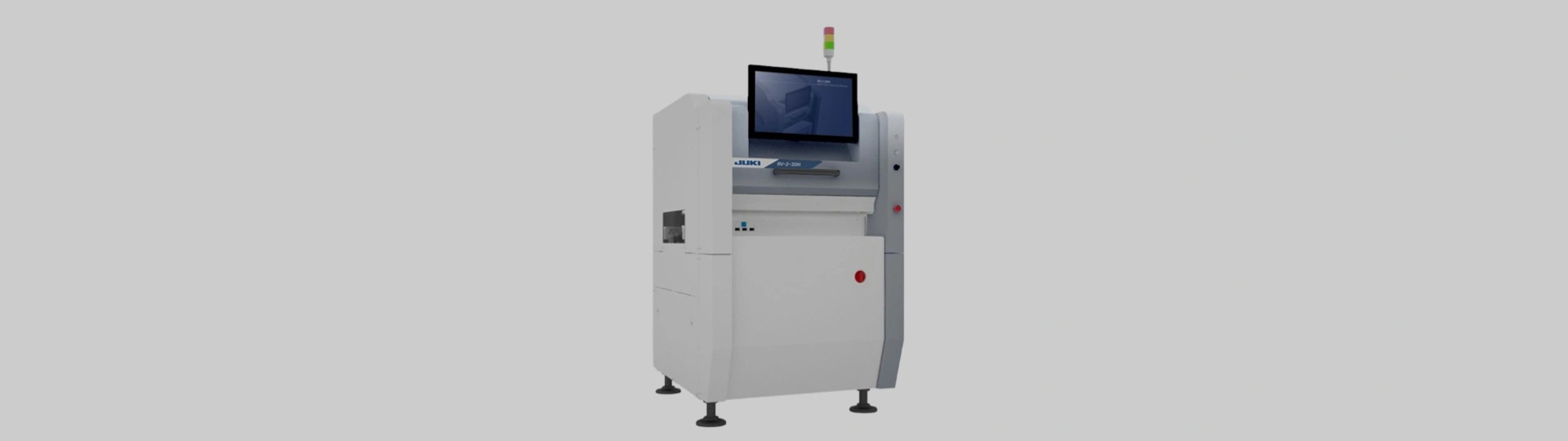

Ensuring Quality Control in PCB Assembly with an SMT Inspection Machine

An SMT inspection machine safeguards PCB quality through real-time defect detection, identifying misaligned components, solder defects, or missing parts with 99.95% accuracy. AI-driven AOI and SPI systems analyze 3D solder paste profiles and component placement, preventing downstream failures. Automated reporting aligns with IPC-A-610 standards, ensuring compliance for automotive, medical, and aerospace electronics. By catching errors early, it reduces scrap costs by 40% and accelerates time-to-market. IoT integration enables predictive analytics, optimizing process parameters for zero-defect outcomes. Trusted for high-reliability manufacturing, this machine transforms quality control into a proactive, data-driven pillar of precision assembly.

How AI-Powered SMT Inspection Machines Improve Defect Detection in Electronics

AI-powered SMT inspection machines revolutionize defect detection by learning from millions of PCB images to identify subtle flaws—micro-cracks, tombstoning, or insufficient solder—with 99.98% accuracy. Deep learning algorithms adapt to new component geometries (e.g., 0.2mm-pitch BGAs, 008004 chips), reducing false alarms by 70% versus rule-based systems. Real-time feedback adjusts placement or soldering parameters, preventing batch defects. Compatible with IPC-A-610G and automotive AEC-Q100, they excel in EV, 5G, and medical device production. By transforming raw data into actionable insights, these machines slash rework costs by 50% and elevate quality control to a predictive, self-optimizing process—where AI meets industrial precision.